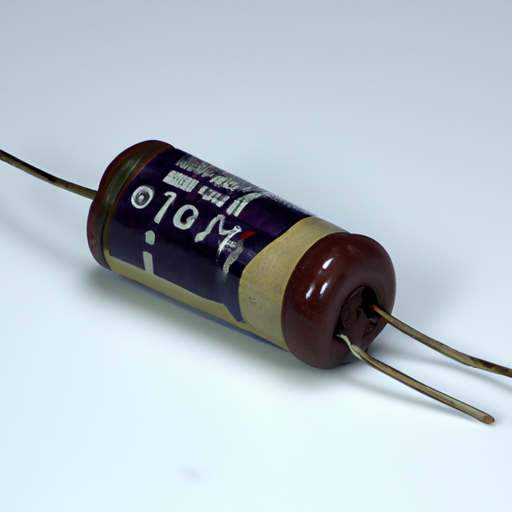

A wire wound resistor is a type of electrical resistor that is made by winding a resistive wire around a core material. This type of resistor is commonly used in a variety of electronic devices and circuits to limit the flow of electric current and to provide a specific level of resistance. Wire wound resistors are known for their high precision and stability, making them ideal for applications where accuracy is crucial.The construction of a wire wound resistor typically consists of a resistive wire, such as nichrome or constantan, that is wound around a ceramic or fiberglass core. The wire is wound in a specific pattern and density to achieve the desired resistance value. The ends of the wire are then connected to terminals that allow for easy integration into a circuit.One of the key advantages of wire wound resistors is their high power handling capability. Due to their construction, wire wound resistors can dissipate large amounts of heat without affecting their performance. This makes them suitable for high-power applications where other types of resistors may fail.Wire wound resistors are also known for their high precision and stability. The winding process allows for precise control over the resistance value, resulting in resistors that have low tolerance levels and excellent temperature stability. This makes wire wound resistors ideal for applications where accuracy is critical, such as in precision measuring instruments or medical devices.In addition to their precision and stability, wire wound resistors are also known for their durability and reliability. The robust construction of these resistors allows them to withstand harsh operating conditions, such as high temperatures, vibrations, and humidity. This makes wire wound resistors suitable for use in a wide range of industrial and automotive applications.Wire wound resistors are available in a variety of configurations, including axial lead, radial lead, and surface mount. They are also available in different resistance values, power ratings, and tolerance levels to meet the specific requirements of different applications. Some wire wound resistors are also designed with additional features, such as adjustable resistance or temperature compensation, to further enhance their performance.In conclusion, wire wound resistors are a versatile and reliable type of resistor that is widely used in electronic devices and circuits. Their high precision, stability, and power handling capability make them ideal for applications where accuracy and durability are essential. Whether used in industrial machinery, automotive systems, or consumer electronics, wire wound resistors play a crucial role in ensuring the proper functioning of electronic devices and circuits.

Stainless steel resistor devices are essential components in various electronic applications, providing precise resistance values and high reliability. When it comes to purchasing these components, there are several different models that buyers can choose from, each with its own advantages and considerations. In this article, we will explore the purchasing models for the latest stainless steel resistor device components, including traditional distribution channels, online marketplaces, and direct sourcing from manufacturers.Traditional Distribution ChannelsOne of the most common ways to purchase stainless steel resistor devices is through traditional distribution channels. This involves buying the components from authorized distributors who source them from manufacturers and sell them to customers. Distributors typically have a wide range of products in stock and can provide technical support and assistance with product selection.One of the main advantages of purchasing through traditional distribution channels is the convenience and reliability of working with established suppliers. Distributors often have long-standing relationships with manufacturers and can offer competitive pricing and fast delivery times. They also provide a level of assurance that the components are genuine and meet the required specifications.However, one potential downside of purchasing through traditional distribution channels is the higher cost compared to other purchasing models. Distributors add a markup to the price of the components, which can increase the overall cost of the purchase. Additionally, distributors may have limited stock availability or may not carry the specific components that a buyer is looking for.Online MarketplacesAnother popular purchasing model for stainless steel resistor devices is through online marketplaces such as Amazon, eBay, and Alibaba. These platforms allow buyers to browse a wide selection of products from various sellers and compare prices and specifications. Online marketplaces offer convenience and accessibility, allowing buyers to purchase components from anywhere in the world.One of the main advantages of purchasing through online marketplaces is the competitive pricing and the ability to find rare or hard-to-find components. Sellers on these platforms often offer lower prices than traditional distributors, as they have lower overhead costs and can reach a larger customer base. Online marketplaces also provide a platform for buyers to read reviews and ratings from other customers, helping them make informed purchasing decisions.However, there are some potential drawbacks to purchasing through online marketplaces. One concern is the risk of buying counterfeit or substandard components from unverified sellers. Buyers should exercise caution and verify the authenticity of the components before making a purchase. Additionally, shipping times and costs can vary depending on the seller's location and shipping method, which may impact the overall purchasing experience.Direct Sourcing from ManufacturersA third purchasing model for stainless steel resistor devices is to source directly from manufacturers. This involves contacting the manufacturer directly to inquire about pricing, availability, and technical specifications. Direct sourcing allows buyers to establish a direct relationship with the manufacturer and potentially negotiate better pricing and terms.One of the main advantages of sourcing directly from manufacturers is the potential cost savings and access to exclusive products. By cutting out the middleman, buyers can often secure lower prices and better terms for bulk orders. Manufacturers can also provide technical support and customization options to meet specific requirements.However, there are some challenges associated with sourcing directly from manufacturers. One concern is the minimum order quantities (MOQs) that manufacturers may require, which can be prohibitive for small buyers. Communication and logistics can also be more complex when dealing directly with manufacturers, especially if they are located overseas.In conclusion, there are several purchasing models for the latest stainless steel resistor device components, each with its own advantages and considerations. Traditional distribution channels offer convenience and reliability but may come with higher costs. Online marketplaces provide competitive pricing and accessibility but carry the risk of counterfeit products. Direct sourcing from manufacturers can lead to cost savings and customization options but may require higher MOQs and more complex logistics. Ultimately, buyers should consider their specific needs and preferences when choosing a purchasing model for stainless steel resistor devices.

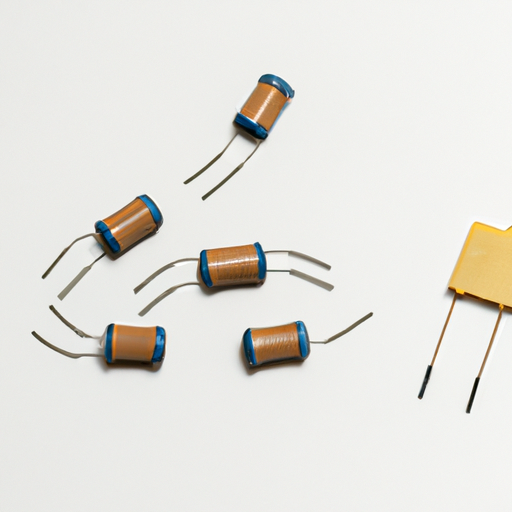

Capacitors are essential components in electronic circuits, used to store and release electrical energy. They come in various shapes and sizes, and are manufactured by numerous brands. In this article, we will discuss some of the most popular capacitor brands and their common models.1. Panasonic

Panasonic is a well-known brand in the electronics industry, and they produce a wide range of capacitors for various applications. Some of their popular capacitor models include the ECQ series, which are film capacitors known for their high reliability and performance. Another common model is the EEU series, which are aluminum electrolytic capacitors suitable for power supply and filtering applications.2. Nichicon

Nichicon is a Japanese capacitor manufacturer with a long history of producing high-quality capacitors. One of their popular models is the UFW series, which are aluminum electrolytic capacitors designed for use in audio equipment and other high-end applications. The VR series is another common model from Nichicon, known for its long lifespan and stability.3. Rubycon

Rubycon is another Japanese capacitor brand that is highly regarded for its quality and reliability. Their ZL series of aluminum electrolytic capacitors are widely used in power supply and industrial applications. The YXF series is another popular model from Rubycon, known for its low impedance and high ripple current handling capabilities.4. Vishay

Vishay is a global manufacturer of electronic components, including capacitors. Their 293D series of aluminum electrolytic capacitors are commonly used in power supply and lighting applications. The 225P series of film capacitors from Vishay are also popular for their high performance and reliability.5. Murata

Murata is a leading manufacturer of electronic components, including capacitors. Their GRM series of multilayer ceramic capacitors are widely used in consumer electronics and automotive applications. The GCM series of aluminum electrolytic capacitors from Murata are also popular for their high reliability and performance.6. TDK

TDK is a well-known brand in the electronics industry, and they produce a wide range of capacitors for various applications. Their C series of multilayer ceramic capacitors are popular for their high capacitance and small size. The FK series of aluminum electrolytic capacitors from TDK are also commonly used in power supply and filtering applications.7. KEMET

KEMET is a global manufacturer of electronic components, including capacitors. Their Tantalum capacitors are widely used in high-performance applications due to their high capacitance and low ESR. The C0G series of ceramic capacitors from KEMET are also popular for their stability and reliability.In conclusion, there are many capacitor brands and models available in the market, each with its own unique features and applications. The brands mentioned in this article are some of the most popular and trusted in the industry, known for their quality and reliability. When choosing a capacitor for your electronic project, it is important to consider the specific requirements of your application and select a capacitor that meets those needs.

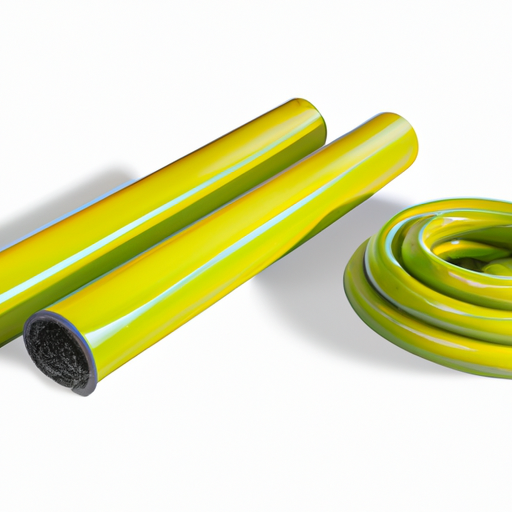

Yellow-green hot tubs are a popular choice for many homeowners looking to add a touch of color and style to their outdoor living space. However, when it comes to purchasing a yellow-green hot tub, it is important to ensure that the product meets certain standards to ensure safety, quality, and performance. In this article, we will discuss the product standards for yellow-green hot tubs to help you make an informed decision when purchasing one for your home.1. Material Quality:

One of the most important product standards for yellow-green hot tubs is the quality of the materials used in its construction. The tub should be made from durable and weather-resistant materials that can withstand the elements and provide long-lasting performance. High-quality materials such as acrylic, fiberglass, or stainless steel are commonly used in the construction of hot tubs to ensure durability and longevity.2. Safety Features:

Another important product standard for yellow-green hot tubs is the presence of safety features to protect users from potential hazards. Safety features such as slip-resistant surfaces, handrails, and secure covers are essential to prevent accidents and injuries while using the hot tub. Additionally, the hot tub should be equipped with a reliable heating system and temperature controls to ensure safe and comfortable operation.3. Energy Efficiency:

In today's environmentally conscious world, energy efficiency is a key consideration when purchasing a yellow-green hot tub. The product should be designed to minimize energy consumption and reduce operating costs without compromising performance. Look for hot tubs that are equipped with energy-efficient pumps, heaters, and insulation to help you save money on your utility bills while enjoying the benefits of a relaxing soak.4. Water Quality:

Maintaining clean and sanitary water is essential for the health and safety of hot tub users. Yellow-green hot tubs should be equipped with effective filtration systems, water treatment options, and sanitation methods to ensure that the water remains clean and free of contaminants. Regular maintenance and proper water chemistry testing are also important to keep the water in the hot tub safe and inviting.5. Design and Aesthetics:

While product standards focus on safety and performance, the design and aesthetics of a yellow-green hot tub are also important considerations for many homeowners. The tub should be visually appealing and complement the overall look of your outdoor space. Choose a hot tub with a stylish design, attractive color options, and customizable features to create a relaxing and inviting atmosphere for you and your guests.In conclusion, when shopping for a yellow-green hot tub, it is important to consider the product standards outlined above to ensure that you are investing in a high-quality and reliable product. By choosing a hot tub that meets these standards, you can enjoy the benefits of a relaxing and rejuvenating soak while enhancing the beauty and functionality of your outdoor living space. Remember to research different brands and models, read customer reviews, and consult with a professional hot tub dealer to find the perfect yellow-green hot tub for your home.

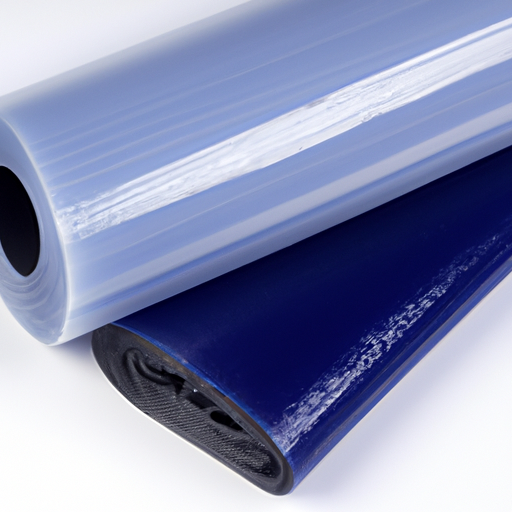

Silicon resin glass fiber sleeve is a versatile and durable product that is used in a wide range of industries for various applications. This product is made from high-quality silicon resin and glass fibers, which are woven together to create a strong and flexible sleeve that can withstand high temperatures, abrasion, and chemical exposure. Silicon resin glass fiber sleeve is available in different sizes and configurations to meet the specific needs of different industries.There are several key product categories of silicon resin glass fiber sleeve, each designed for specific applications and environments. Some of the key product categories include:1. High-temperature sleeves: Silicon resin glass fiber sleeves are designed to withstand high temperatures, making them ideal for use in applications where heat resistance is essential. These sleeves can withstand temperatures up to 1000 degrees Fahrenheit, making them suitable for use in automotive, aerospace, and industrial applications.2. Abrasion-resistant sleeves: Silicon resin glass fiber sleeves are also highly abrasion-resistant, making them ideal for use in applications where the sleeve may come into contact with rough surfaces or sharp edges. These sleeves are commonly used in industrial machinery, conveyor systems, and other applications where abrasion resistance is important.3. Chemical-resistant sleeves: Silicon resin glass fiber sleeves are resistant to a wide range of chemicals, making them ideal for use in applications where the sleeve may come into contact with corrosive substances. These sleeves are commonly used in chemical processing plants, laboratories, and other environments where chemical resistance is essential.4. Electrical insulation sleeves: Silicon resin glass fiber sleeves are also used as electrical insulation sleeves in applications where electrical conductivity needs to be prevented. These sleeves are commonly used in electrical wiring, motors, and other electrical components to provide insulation and protection against electrical hazards.5. Thermal insulation sleeves: Silicon resin glass fiber sleeves are also used as thermal insulation sleeves in applications where heat insulation is required. These sleeves are commonly used in HVAC systems, industrial ovens, and other applications where thermal insulation is essential to prevent heat loss or gain.Overall, silicon resin glass fiber sleeves are a versatile and durable product that can be used in a wide range of industries for various applications. Whether you need high-temperature resistance, abrasion resistance, chemical resistance, electrical insulation, or thermal insulation, there is a silicon resin glass fiber sleeve that is suitable for your specific needs. With their high-quality construction and performance capabilities, silicon resin glass fiber sleeves are a reliable and cost-effective solution for many industrial applications.

Glass fiber sleeves are versatile products that are commonly used in a variety of industries for their excellent thermal insulation, electrical insulation, and abrasion resistance properties. These sleeves are made from high-quality glass fibers that are woven together to create a strong and durable material that can withstand high temperatures and harsh environments. In this article, we will explore the commonly used glass fiber sleeve products and their applications in different industries.1. Silicone Coated Glass Fiber SleevesSilicone coated glass fiber sleeves are one of the most commonly used glass fiber sleeve products. These sleeves are coated with a layer of silicone that provides additional protection against heat, chemicals, and abrasion. The silicone coating also makes the sleeves more flexible and easier to handle, making them ideal for applications where flexibility is important. Silicone coated glass fiber sleeves are commonly used in the automotive industry for protecting wires and cables from heat and abrasion, as well as in the aerospace industry for insulating electrical components.2. Acrylic Coated Glass Fiber SleevesAcrylic coated glass fiber sleeves are another popular choice for thermal insulation and electrical insulation applications. These sleeves are coated with a layer of acrylic resin that provides excellent resistance to heat, chemicals, and abrasion. The acrylic coating also helps to improve the flexibility and durability of the sleeves, making them suitable for a wide range of applications. Acrylic coated glass fiber sleeves are commonly used in the electronics industry for insulating wires and cables, as well as in the construction industry for protecting pipes and hoses from heat and abrasion.3. Vermiculite Coated Glass Fiber SleevesVermiculite coated glass fiber sleeves are a specialized type of glass fiber sleeve that is coated with a layer of vermiculite, a naturally occurring mineral that expands when heated. This coating provides excellent thermal insulation properties, making vermiculite coated glass fiber sleeves ideal for high-temperature applications. These sleeves are commonly used in the industrial sector for insulating pipes, hoses, and cables in high-temperature environments, such as foundries and steel mills.4. Aluminum Coated Glass Fiber SleevesAluminum coated glass fiber sleeves are another commonly used glass fiber sleeve product that provides excellent heat reflection and thermal insulation properties. These sleeves are coated with a layer of aluminum that reflects heat away from the surface, helping to protect wires, cables, and hoses from high temperatures. Aluminum coated glass fiber sleeves are commonly used in the automotive industry for insulating exhaust systems and in the aerospace industry for protecting electrical components from heat.5. PTFE Coated Glass Fiber SleevesPTFE coated glass fiber sleeves are a specialized type of glass fiber sleeve that is coated with a layer of polytetrafluoroethylene (PTFE), a synthetic fluoropolymer that provides excellent chemical resistance and low friction properties. These sleeves are commonly used in the chemical industry for protecting pipes and hoses from corrosive chemicals, as well as in the food industry for insulating heating elements and conveyor belts. PTFE coated glass fiber sleeves are also used in the medical industry for protecting medical devices and equipment from contamination.In conclusion, glass fiber sleeves are versatile products that are commonly used in a variety of industries for their excellent thermal insulation, electrical insulation, and abrasion resistance properties. Whether you need a silicone coated sleeve for protecting wires and cables in the automotive industry or a vermiculite coated sleeve for insulating pipes in a high-temperature environment, there is a glass fiber sleeve product available to meet your specific needs. With their durability, flexibility, and resistance to heat and chemicals, glass fiber sleeves are an essential component in many industrial applications.

Heating tubes are an essential component in many industrial processes, providing the necessary heat to achieve specific temperatures for various applications. These tubes are commonly used in industries such as manufacturing, food processing, and chemical processing, among others. In this article, we will explore the different types of heating tubes, their applications, and the importance of proper maintenance to ensure optimal performance.Types of Heating TubesThere are several types of heating tubes available on the market, each designed for specific applications and operating conditions. Some of the most common types include:1. Immersion Heating Tubes: These tubes are submerged in a liquid or gas to heat it directly. They are commonly used in water heaters, boilers, and industrial processes that require precise temperature control.2. Tubular Heating Elements: These are versatile heating elements that can be bent or shaped to fit specific applications. They are commonly used in ovens, dryers, and other heating equipment.3. Infrared Heating Tubes: These tubes emit infrared radiation to heat objects or surfaces directly. They are commonly used in heating processes that require rapid heating or drying.4. Quartz Heating Tubes: These tubes are made of quartz glass and are used in applications that require high temperatures and resistance to chemical corrosion. They are commonly used in semiconductor manufacturing, laboratory equipment, and medical devices.Applications of Heating TubesHeating tubes are used in a wide range of applications across various industries. Some of the common applications include:1. Heating liquids and gases in industrial processes such as chemical processing, food processing, and pharmaceutical manufacturing.2. Heating surfaces or objects in drying processes, such as in ovens, dryers, and kilns.3. Providing heat for comfort in residential and commercial buildings, such as in water heaters and HVAC systems.4. Heating materials in manufacturing processes, such as in plastic molding, metal fabrication, and glass production.Importance of Proper MaintenanceProper maintenance of heating tubes is essential to ensure optimal performance and longevity. Some of the key maintenance practices include:1. Regular cleaning: Heating tubes can accumulate dirt, debris, and other contaminants over time, which can reduce their efficiency. Regular cleaning with a soft brush or cloth can help remove these deposits and improve heat transfer.2. Inspecting for damage: Heating tubes can develop cracks, corrosion, or other damage over time, which can affect their performance. Regular inspections can help identify any issues early and prevent costly repairs or replacements.3. Checking for proper operation: Monitoring the temperature, pressure, and other operating conditions of heating tubes is essential to ensure they are functioning correctly. Any deviations from the normal operating parameters should be investigated and addressed promptly.4. Replacing worn-out parts: Heating tubes have a limited lifespan and will eventually wear out. It is important to replace worn-out parts, such as heating elements or insulation, to maintain optimal performance and prevent downtime.In conclusion, heating tubes are an essential component in many industrial processes, providing the necessary heat to achieve specific temperatures for various applications. Understanding the different types of heating tubes, their applications, and the importance of proper maintenance is crucial to ensure optimal performance and longevity. By following the recommended maintenance practices, heating tubes can continue to provide reliable and efficient heat for years to come.

Capacitor protection products are essential components in electrical systems to ensure the longevity and reliability of capacitors. These products help prevent damage from overvoltage, overcurrent, and other electrical faults that can occur in the system. Proper training on capacitor protection products is crucial for electrical engineers, technicians, and other professionals working with electrical systems to ensure they are used correctly and effectively. In this article, we will discuss some key considerations for training on capacitor protection products.1. Understanding the basics of capacitors and their protectionBefore delving into the specifics of capacitor protection products, it is important to have a solid understanding of capacitors themselves. Capacitors are electronic components that store and release electrical energy. They are commonly used in electrical systems to filter out noise, stabilize voltage, and store energy. Capacitors are susceptible to damage from overvoltage, overcurrent, and other electrical faults, which is why capacitor protection products are necessary.Training on capacitor protection products should cover the basics of how capacitors work, common types of capacitors, and the potential risks they face in electrical systems. This foundational knowledge will help participants understand the importance of capacitor protection products and how they can help mitigate these risks.2. Types of capacitor protection productsThere are various types of capacitor protection products available on the market, each designed to protect capacitors from specific types of electrical faults. Some common types of capacitor protection products include overvoltage protection devices, overcurrent protection devices, and surge protection devices.Training on capacitor protection products should cover the different types available, their functions, and how they are installed and used in electrical systems. Participants should also learn how to select the appropriate protection products based on the specific requirements of the system and the type of capacitors being used.3. Installation and maintenance best practicesProper installation and maintenance of capacitor protection products are essential to ensure they function effectively and provide the necessary protection to capacitors. Training on capacitor protection products should include best practices for installation, such as proper wiring, grounding, and placement of protection devices.Participants should also learn how to conduct regular maintenance checks on capacitor protection products to ensure they are working correctly. This may include testing for proper functionality, inspecting for signs of damage or wear, and replacing any faulty components as needed.4. Troubleshooting and troubleshooting techniquesDespite the best efforts to protect capacitors, electrical faults can still occur in systems. Training on capacitor protection products should include troubleshooting techniques to identify and resolve issues with protection devices. Participants should learn how to diagnose common problems, such as overvoltage or overcurrent events, and how to take corrective action to prevent damage to capacitors.Additionally, participants should be trained on how to respond to emergency situations involving capacitor protection products, such as power surges or short circuits. This may include knowing how to safely disconnect power to the system, isolate the faulty component, and make necessary repairs or replacements.5. Compliance and safety regulationsCompliance with industry standards and safety regulations is essential when working with capacitor protection products. Training on capacitor protection products should cover relevant standards and regulations, such as those set by organizations like the Institute of Electrical and Electronics Engineers (IEEE) and the National Electrical Code (NEC).Participants should also be trained on safety protocols when working with capacitor protection products, including proper handling of electrical components, use of personal protective equipment, and emergency response procedures. This will help ensure the safety of personnel and the integrity of the electrical system.In conclusion, training on capacitor protection products is essential for professionals working with electrical systems to ensure the proper use and maintenance of these critical components. By understanding the basics of capacitors, types of protection products, installation and maintenance best practices, troubleshooting techniques, and compliance and safety regulations, participants can effectively protect capacitors from electrical faults and ensure the reliability of the system. Investing in comprehensive training on capacitor protection products will ultimately lead to improved performance, reduced downtime, and increased safety in electrical systems.

The Yellow-green hot tub models from Hot Spot are a popular choice for those looking to add a touch of luxury and relaxation to their outdoor space. These hot tubs are known for their sleek design, advanced features, and high-quality construction. In this article, we will explore the price of these hot tub models and what sets them apart from other options on the market.The price of the Yellow-green hot tub models from Hot Spot can vary depending on the specific model and features you choose. On average, these hot tubs range in price from $5,000 to $10,000. This price range puts them in the mid to high-end category of hot tubs, making them a significant investment for many homeowners.One of the main factors that contribute to the price of these hot tub models is the size and seating capacity. The Yellow-green hot tub models come in a range of sizes, from smaller two-person tubs to larger models that can accommodate up to seven or eight people. The larger the hot tub and the more seating capacity it has, the higher the price is likely to be.Another factor that can affect the price of these hot tub models is the features and amenities included. Hot Spot offers a range of advanced features for their hot tubs, such as LED lighting, waterfalls, built-in speakers, and massage jets. The more features and amenities a hot tub has, the higher the price is likely to be. However, these features can greatly enhance the overall experience of using the hot tub and make it worth the investment for many homeowners.In addition to the size and features, the construction and materials used in the Yellow-green hot tub models also contribute to their price. Hot Spot is known for using high-quality materials and construction techniques to ensure that their hot tubs are durable and long-lasting. This attention to detail and quality craftsmanship can drive up the price of these hot tub models, but it also ensures that they will provide years of enjoyment and relaxation for their owners.While the price of the Yellow-green hot tub models from Hot Spot may be higher than some other options on the market, many homeowners find that the investment is well worth it. These hot tubs offer a luxurious and relaxing experience that can help to improve overall well-being and quality of life. Whether you are looking to unwind after a long day, entertain guests, or simply enjoy some time outdoors, a hot tub can provide the perfect setting.In conclusion, the Yellow-green hot tub models from Hot Spot are a top choice for those looking to add a touch of luxury and relaxation to their outdoor space. While the price of these hot tub models may be higher than some other options on the market, the quality construction, advanced features, and overall experience they provide make them a worthwhile investment for many homeowners. If you are considering purchasing a hot tub, the Yellow-green models from Hot Spot are definitely worth a closer look.

Hot cable attachment is a versatile and essential tool for any fitness enthusiast looking to take their workouts to the next level. This innovative piece of equipment offers a wide range of benefits and can be used for a variety of exercises to target different muscle groups. In this article, we will explore the product levels of hot cable attachment and how it can enhance your fitness routine.Level 1: Basic Hot Cable AttachmentThe basic hot cable attachment is a simple yet effective tool that can be easily attached to any cable machine. It typically consists of a handle or bar with a cable attached to it, allowing for a wide range of motion and resistance levels. This level is perfect for beginners or those looking to add some variety to their workouts without investing in more advanced equipment.With the basic hot cable attachment, you can perform a variety of exercises such as bicep curls, tricep extensions, shoulder presses, and rows. The adjustable resistance levels make it easy to customize your workout and target specific muscle groups. This level is also great for rehabilitation exercises or for those recovering from injuries, as it allows for controlled and low-impact movements.Level 2: Intermediate Hot Cable AttachmentThe intermediate hot cable attachment offers more advanced features and options for a more challenging workout. This level may include additional attachments such as ropes, bars, or handles to target different muscle groups and add variety to your exercises. The resistance levels may also be more adjustable, allowing for a greater range of motion and intensity.With the intermediate hot cable attachment, you can perform a wider range of exercises such as cable crossovers, lat pulldowns, woodchoppers, and oblique twists. These exercises target multiple muscle groups simultaneously, providing a full-body workout that can help improve strength, endurance, and flexibility. The versatility of this level makes it suitable for both beginners and more experienced fitness enthusiasts looking to take their workouts to the next level.Level 3: Advanced Hot Cable AttachmentThe advanced hot cable attachment is designed for serious athletes and fitness enthusiasts who are looking for a high-intensity workout. This level may include additional features such as multiple cable attachments, adjustable pulley systems, and heavier resistance levels to challenge even the strongest of individuals. The advanced hot cable attachment is perfect for those looking to build muscle, increase power, and improve overall athletic performance.With the advanced hot cable attachment, you can perform a wide range of dynamic and explosive exercises such as cable squats, cable lunges, cable rows, and cable push presses. These exercises require coordination, balance, and strength, making them ideal for athletes looking to improve their performance in sports such as basketball, football, or track and field. The advanced hot cable attachment is also great for bodybuilders looking to sculpt and define their muscles with targeted resistance training.In conclusion, hot cable attachment is a versatile and effective tool for enhancing your fitness routine at any level. Whether you are a beginner looking to add variety to your workouts or an advanced athlete looking to push your limits, hot cable attachment offers a wide range of benefits and options for customization. By incorporating hot cable attachment into your workouts, you can improve strength, endurance, flexibility, and overall athletic performance. So why wait? Take your workouts to the next level with hot cable attachment today!