Choosing the right high temperature fiber sleeve or thermal tube can be a crucial decision, especially when it comes to protecting sensitive equipment or ensuring the safety of personnel. In this article, we will discuss the factors to consider when selecting a spot high temperature fiber sleeve/thermal tube. By the end of this article, you will have a clear understanding of the key considerations and be able to make an informed decision.

2. Material Composition: High temperature fiber sleeves and thermal tubes are made from various materials, including fiberglass, silicone, ceramic, and basalt. Each material has its own unique properties and advantages. For example, fiberglass sleeves are cost-effective and provide excellent thermal insulation, while silicone sleeves offer flexibility and resistance to chemicals. Consider the specific requirements of your application and choose a material that best suits your needs.

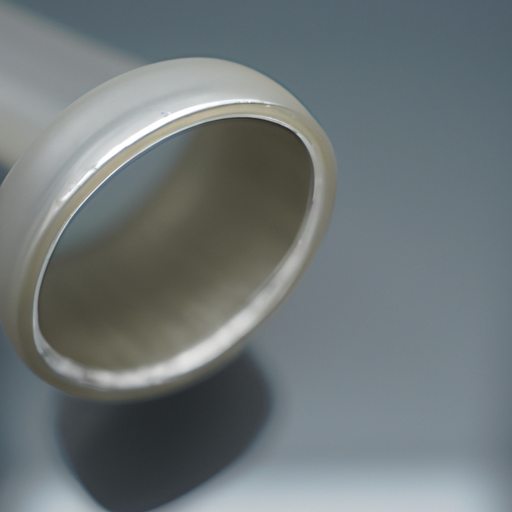

3. Size and Diameter: The size and diameter of the sleeve or tube are crucial factors to consider. Measure the dimensions of the object or area that needs protection and choose a sleeve that fits snugly. It is important to ensure that the sleeve covers the entire surface area to provide effective insulation and protection.

4. Flexibility and Ease of Installation: Consider the flexibility and ease of installation of the high temperature sleeve or tube. Some sleeves are more rigid and may require additional effort to install, while others are more flexible and can be easily wrapped around irregular shapes. Evaluate the installation process and choose a sleeve that suits your requirements.

5. Chemical Resistance: If the high temperature sleeve or tube will be exposed to chemicals or corrosive substances, it is essential to choose a material that is resistant to these elements. Silicone sleeves, for example, offer excellent resistance to chemicals, oils, and solvents. Ensure that the chosen sleeve can withstand the specific chemicals it will encounter in your application.

6. Durability and Longevity: Consider the durability and longevity of the high temperature sleeve or tube. Evaluate the product's resistance to wear, tear, and degradation over time. Look for sleeves that are known for their longevity and can withstand the demands of your application without frequent replacement.

7. Compliance with Industry Standards: Depending on your industry or application, there may be specific standards or regulations that the high temperature sleeve or tube needs to comply with. Ensure that the chosen product meets all relevant industry standards and certifications to guarantee its quality and performance.

8. Cost: Finally, consider the cost of the high temperature sleeve or tube. While it is important to stay within budget, it is equally crucial to prioritize quality and performance. Cheaper options may not provide the necessary protection or durability, leading to potential risks or frequent replacements. Evaluate the cost in relation to the product's features, performance, and expected lifespan.

In conclusion, choosing the right high temperature fiber sleeve or thermal tube requires careful consideration of factors such as temperature range, material composition, size, flexibility, chemical resistance, durability, compliance with industry standards, and cost. By thoroughly evaluating these factors and understanding your specific requirements, you can make an informed decision and select a spot high temperature fiber sleeve or thermal tube that best suits your needs.