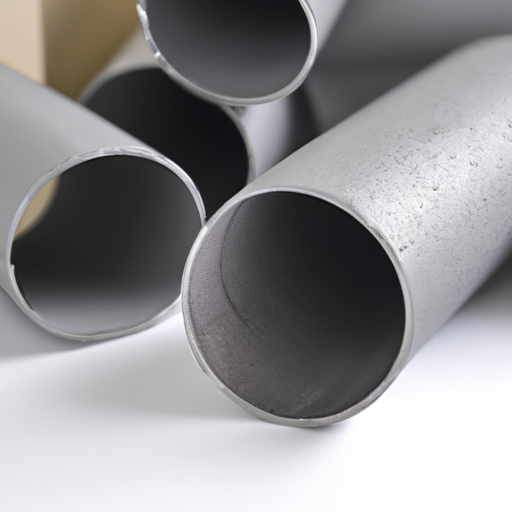

PVC heat tubes are versatile and widely used in various industries due to their excellent thermal insulation properties. These tubes are made from polyvinyl chloride (PVC), a synthetic plastic polymer known for its durability, flexibility, and resistance to heat and chemicals. PVC heat tubes are designed to withstand high temperatures and are commonly used in applications such as electrical insulation, automotive, HVAC systems, and industrial processes.

1. Electrical Insulation: One of the primary applications of PVC heat tubes is electrical insulation. These tubes are used to protect electrical wires and cables from heat, moisture, and other environmental factors. PVC heat tubes provide excellent electrical insulation properties, ensuring the safety and reliability of electrical systems. They are commonly used in residential, commercial, and industrial buildings, as well as in automotive and aerospace industries.

2. Automotive Industry: PVC heat tubes find extensive use in the automotive industry due to their ability to withstand high temperatures and resist chemicals and oils. They are used in various applications such as fuel lines, coolant hoses, and air conditioning systems. PVC heat tubes help maintain the integrity and efficiency of automotive systems, ensuring optimal performance and safety.

3. HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems require efficient insulation to maintain temperature control and energy efficiency. PVC heat tubes are used in HVAC systems to insulate pipes, ducts, and other components. These tubes prevent heat loss or gain, reducing energy consumption and improving overall system performance. PVC heat tubes also provide protection against condensation and moisture, preventing mold growth and maintaining indoor air quality.

4. Industrial Processes: In industrial settings, PVC heat tubes are used in various applications such as steam lines, chemical processing, and thermal insulation for machinery and equipment. These tubes can withstand high temperatures, making them suitable for industrial processes that involve heat transfer or require thermal insulation. PVC heat tubes also offer resistance to chemicals, acids, and alkalis, ensuring durability and longevity in harsh industrial environments.

5. Plumbing and Water Systems: PVC heat tubes are commonly used in plumbing and water systems due to their resistance to corrosion, chemicals, and high temperatures. These tubes are used for hot water supply lines, drainage systems, and irrigation applications. PVC heat tubes provide reliable and long-lasting performance, ensuring the efficient flow of water and preventing leaks or damage to the plumbing infrastructure.

Manufacturing Process and Quality Standards: PVC heat tubes are manufactured through an extrusion process, where PVC resin is melted and forced through a die to form the desired shape and size. The extruded tubes are then cooled and cut into specific lengths. Quality standards play a crucial role in ensuring the performance and safety of PVC heat tubes. Manufacturers adhere to international standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) to ensure the quality, durability, and safety of their products.

Considerations for Selecting PVC Heat Tubes: When selecting PVC heat tubes for specific applications, several factors need to be considered:

1. Temperature Range: Determine the maximum and minimum temperatures the tube will be exposed to and select a PVC heat tube that can withstand those temperatures without deformation or degradation.

2. Chemical Resistance: Consider the chemicals or substances the tube will come into contact with and choose a PVC heat tube that offers resistance to those chemicals to prevent damage or deterioration.

3. Flexibility and Size: Evaluate the flexibility and size requirements of the application. PVC heat tubes are available in various sizes and flexibility levels, allowing for customization based on specific needs.

4. Insulation Properties: Assess the thermal insulation properties of the tube, such as its ability to prevent heat loss or gain. This is particularly important in applications where energy efficiency is a priority.

5. Compliance with Standards: Ensure that the PVC heat tube complies with relevant industry standards and regulations to guarantee its quality, safety, and performance.

In conclusion, PVC heat tubes are essential components in various industries, offering excellent thermal insulation properties, durability, and resistance to heat and chemicals. Their key product categories include electrical insulation, automotive, HVAC systems, industrial processes, and plumbing and water systems. When selecting PVC heat tubes, it is crucial to consider factors such as temperature range, chemical resistance, flexibility, insulation properties, and compliance with standards. By choosing the right PVC heat tube for specific applications, industries can ensure optimal performance, safety, and longevity of their systems and equipment.