The product principle of double-layer silicon resin glass fiber sleeve is a fascinating topic that requires a comprehensive understanding of its composition, manufacturing process, and applications. In this article, we will delve into the intricacies of this innovative product, exploring its features, benefits, and potential uses. By the end of this article, readers will have a thorough understanding of the product principle of double-layer silicon resin glass fiber sleeve.

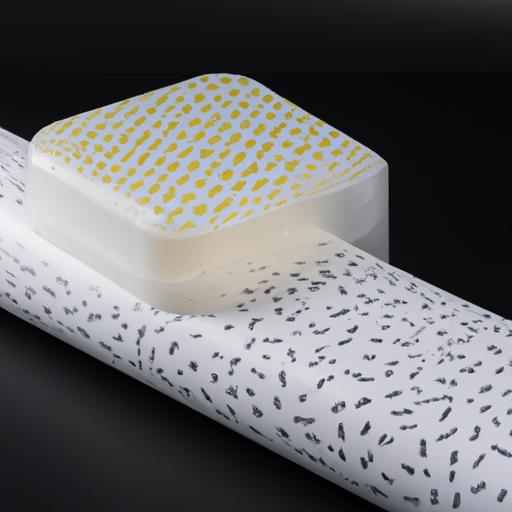

Composition: The double-layer silicon resin glass fiber sleeve is composed of two main layers: the inner layer made of silicon resin and the outer layer made of glass fiber. The silicon resin layer provides excellent electrical insulation properties, while the glass fiber layer enhances the mechanical strength and durability of the sleeve. The combination of these two layers creates a product that is both flexible and robust, making it suitable for a wide range of applications.

Manufacturing Process: The manufacturing process of double-layer silicon resin glass fiber sleeve involves several steps. First, the glass fiber is woven into a tubular shape, forming the outer layer of the sleeve. Then, the silicon resin is applied to the inner surface of the glass fiber layer using a specialized coating technique. This process ensures that the silicon resin adheres firmly to the glass fiber, creating a strong bond between the two layers. Finally, the sleeve is cured at high temperatures to enhance its mechanical properties and ensure its stability.

Features and Benefits: The double-layer silicon resin glass fiber sleeve offers numerous features and benefits that make it a preferred choice in various industries. Firstly, its excellent electrical insulation properties make it ideal for applications where electrical components need to be protected from moisture, dust, and other contaminants. Additionally, the high-temperature resistance of the sleeve allows it to withstand extreme heat, making it suitable for use in environments with elevated temperatures. Moreover, the mechanical strength provided by the glass fiber layer ensures that the sleeve can withstand mechanical stress and abrasion, prolonging the lifespan of the protected components.

Applications: The double-layer silicon resin glass fiber sleeve finds applications in a wide range of industries. In the electrical and electronics industry, it is commonly used to insulate wires, cables, and connectors, protecting them from environmental factors and ensuring reliable performance. In the automotive industry, the sleeve is used to protect wiring harnesses and other electrical components from heat and mechanical stress. Furthermore, it is also utilized in the aerospace industry to shield wires and cables from extreme temperatures and vibrations. The versatility of the double-layer silicon resin glass fiber sleeve makes it an indispensable product in many industrial sectors.

Conclusion: The product principle of double-layer silicon resin glass fiber sleeve is based on the combination of silicon resin and glass fiber, resulting in a product that offers excellent electrical insulation, high-temperature resistance, and mechanical strength. Its unique composition and manufacturing process make it a reliable and versatile solution for protecting wires, cables, and other components in demanding environments. With its wide range of applications and numerous benefits, the double-layer silicon resin glass fiber sleeve is a crucial component in various industries.