What is the Purchase Price of the Latest Thin Film Resistors?

I. Introduction

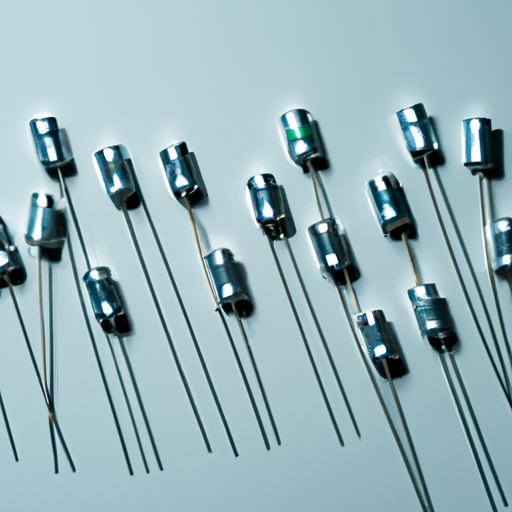

In the world of electronics, resistors play a crucial role in controlling current flow and ensuring circuit stability. Among the various types of resistors, thin film resistors have gained significant attention due to their precision and reliability. This article aims to explore the purchase price of the latest thin film resistors, shedding light on the factors that influence their pricing and providing insights into current market trends.

II. Overview of Thin Film Resistors

A. Explanation of Thin Film Technology

Thin film resistors are made by depositing a thin layer of resistive material onto a substrate, typically using techniques such as sputtering or evaporation. This manufacturing process allows for precise control over the resistor's characteristics, resulting in high accuracy and stability.

1. Manufacturing Process

The production of thin film resistors involves several steps, including substrate preparation, deposition of the resistive layer, patterning, and encapsulation. The choice of substrate material, such as ceramic or glass, can also affect the resistor's performance.

2. Materials Used

Common materials for thin film resistors include nickel-chromium (NiCr), tantalum nitride (TaN), and carbon-based compounds. The selection of materials is critical, as it influences the resistor's temperature coefficient, stability, and overall performance.

B. Comparison with Other Types of Resistors

Thin film resistors are often compared to thick film and wirewound resistors. While thick film resistors are more cost-effective and suitable for high-power applications, thin film resistors excel in precision and stability. Wirewound resistors, on the other hand, are known for their high power ratings but lack the compact size and precision of thin film options.

C. Key Characteristics and Advantages

Thin film resistors offer several advantages, including:

1. **Precision and Stability**: They provide tight tolerances, often as low as 0.1%, making them ideal for applications requiring high accuracy.

2. **Temperature Coefficient**: Thin film resistors typically have low temperature coefficients, ensuring consistent performance across varying temperatures.

3. **Size and Form Factor**: Their compact size allows for integration into small electronic devices, making them a preferred choice in modern applications.

III. Factors Influencing the Purchase Price

A. Material Costs

The cost of materials used in thin film resistors significantly impacts their pricing. For instance, precious metals like gold or platinum can drive up costs, while more common materials may offer a more budget-friendly option.

1. Types of Materials Used

The choice of resistive materials can vary based on the desired performance characteristics. High-performance materials may come at a premium, affecting the overall purchase price.

2. Impact of Raw Material Prices on Overall Cost

Fluctuations in the prices of raw materials can lead to variations in the cost of thin film resistors. For example, if the price of tantalum increases due to supply chain issues, manufacturers may pass these costs onto consumers.

B. Manufacturing Processes

The complexity of the manufacturing process also plays a role in pricing. Advanced techniques that require specialized equipment and skilled labor can increase production costs.

1. Complexity and Technology Involved

Manufacturers investing in cutting-edge technology may produce higher-quality resistors, but this often comes at a higher price point.

2. Scale of Production

Economies of scale can significantly affect pricing. Larger manufacturers may benefit from reduced costs per unit, allowing them to offer competitive pricing compared to smaller producers.

C. Performance Specifications

The performance specifications of thin film resistors, such as tolerance levels, power ratings, and temperature coefficients, can influence their pricing.

1. Tolerance Levels

Resistors with tighter tolerances typically command higher prices due to the increased precision required in their manufacturing.

2. Power Ratings

Higher power ratings often necessitate more robust materials and construction methods, leading to increased costs.

3. Temperature Coefficients

Resistors with superior temperature stability may also be priced higher, reflecting their enhanced performance in demanding applications.

D. Brand Reputation and Market Demand

Brand reputation can significantly influence pricing. Established manufacturers with a track record of quality may charge a premium for their products, while newer entrants may offer lower prices to gain market share.

1. Established Manufacturers vs. New Entrants

Consumers often associate established brands with reliability, which can justify higher prices. However, new entrants may provide competitive alternatives at lower costs.

2. Market Trends and Consumer Preferences

Shifts in market demand can also impact pricing. For instance, as the demand for high-precision components increases in industries like automotive and medical devices, prices for thin film resistors may rise accordingly.

IV. Current Market Prices

A. Overview of Price Ranges for Thin Film Resistors

The price of thin film resistors can vary widely based on specifications and manufacturer. Generally, prices can range from a few cents for basic models to several dollars for high-performance variants.

1. Low-End vs. High-End Products

Low-end thin film resistors may be suitable for less demanding applications, while high-end products are designed for precision tasks in critical systems.

2. Bulk Purchasing vs. Single Unit Pricing

Purchasing in bulk can lead to significant savings, as manufacturers often offer discounts for larger orders. Conversely, single unit pricing may be considerably higher.

B. Examples of Popular Thin Film Resistor Models and Their Prices

Several manufacturers offer a range of thin film resistors, each with unique features and pricing. For example:

1. **Vishay**: Known for high-quality thin film resistors, prices can range from $0.50 to $5.00 depending on specifications.

2. **Yageo**: Offers competitive pricing, with models available from $0.10 to $3.00.

3. **Panasonic**: Their thin film resistors are priced between $0.30 and $4.00, depending on performance characteristics.

C. Analysis of Features and Pricing

When comparing prices, it's essential to consider the features offered. Higher-priced models may provide better performance, tighter tolerances, and superior temperature stability, making them worth the investment for critical applications.

V. Case Studies

A. Analysis of Specific Applications and Their Resistor Requirements

Different industries have varying requirements for thin film resistors, influencing their purchase decisions.

1. Automotive Industry

In automotive applications, thin film resistors are used in precision control systems. The need for reliability and accuracy often leads manufacturers to choose higher-priced models.

2. Medical Devices

Medical devices require components that meet stringent regulatory standards. As a result, thin film resistors used in these applications tend to be on the higher end of the price spectrum.

3. Telecommunications

Telecommunications equipment demands high-performance components to ensure signal integrity. Thin film resistors are often preferred, with prices reflecting their critical role in system performance.

B. Cost Implications of Using Thin Film Resistors in These Applications

While thin film resistors may have a higher upfront cost, their precision and reliability can lead to long-term savings by reducing failures and maintenance costs in critical applications.

VI. Future Trends in Thin Film Resistor Pricing

A. Technological Advancements

As manufacturing technologies continue to evolve, there is potential for cost reductions in thin film resistor production. Innovations such as automation and improved materials may lead to more affordable options in the future.

1. Innovations in Manufacturing

New manufacturing techniques could streamline production processes, reducing labor costs and material waste.

2. Potential for Cost Reduction

As competition increases and technology advances, prices for thin film resistors may become more accessible, benefiting a broader range of applications.

B. Market Predictions

1. Expected Changes in Demand

As industries increasingly rely on precision components, the demand for thin film resistors is expected to grow, potentially driving prices higher in the short term.

2. Impact of Global Economic Factors

Global economic conditions, such as supply chain disruptions or fluctuations in raw material prices, will continue to influence the pricing landscape for thin film resistors.

VII. Conclusion

In summary, the purchase price of thin film resistors is influenced by a variety of factors, including material costs, manufacturing processes, performance specifications, and market dynamics. Understanding these elements is crucial for making informed purchasing decisions. As technology advances and market demands evolve, the landscape for thin film resistors will continue to change, offering both challenges and opportunities for consumers and manufacturers alike.

For those considering the purchase of thin film resistors, it is essential to evaluate specific needs and applications, as well as to stay informed about market trends and pricing fluctuations. Further research into manufacturers and product specifications can lead to better investment decisions in this critical component of modern electronics.

VIII. References

1. Vishay Intertechnology. (2023). Thin Film Resistors Product Catalog.

2. Yageo Corporation. (2023). Thin Film Resistors Overview.

3. Panasonic Corporation. (2023). Precision Resistors for Electronics.

4. Industry Reports on Resistor Market Trends (2023).

5. Various Manufacturer Websites and Product Catalogs.