How to Choose Spot Fuse Resistors

I. Introduction

In the world of electronics, the components we choose can significantly impact the performance and reliability of our devices. One such component is the spot fuse resistor, a critical element in protecting circuits from overcurrent conditions. This blog post will delve into the intricacies of spot fuse resistors, guiding you through the process of selecting the right one for your specific application.

II. Understanding Spot Fuse Resistors

A. What are Spot Fuse Resistors?

Spot fuse resistors are specialized resistors designed to act as fuses in electronic circuits. Their primary function is to limit current flow and protect sensitive components from damage due to excessive current. When the current exceeds a predetermined threshold, the resistor heats up and eventually opens the circuit, effectively "blowing" like a traditional fuse.

1. Function and Purpose

The main purpose of spot fuse resistors is to provide overcurrent protection. They are particularly useful in applications where space is limited, and traditional fuses may not fit. By integrating the fuse function into a resistor, designers can save space and simplify circuit layouts.

2. Applications in Electronics

Spot fuse resistors find applications in various fields, including consumer electronics, automotive systems, industrial equipment, and medical devices. They are commonly used in power supplies, LED drivers, and other circuits where overcurrent protection is essential.

B. Types of Spot Fuse Resistors

Spot fuse resistors come in various types, each suited for different applications.

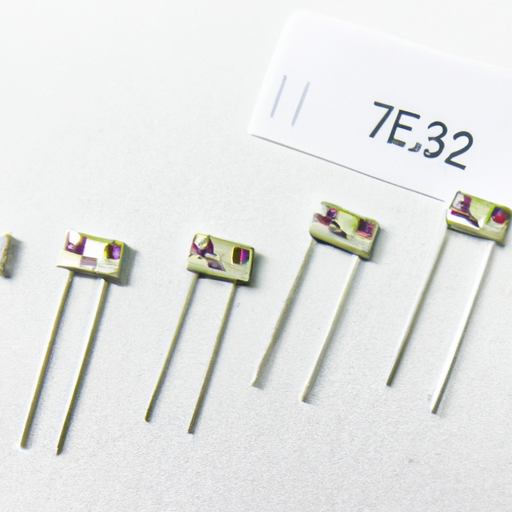

1. Surface Mount vs. Through-Hole

Surface mount spot fuse resistors are designed for automated assembly processes and are typically smaller, making them ideal for compact devices. In contrast, through-hole resistors are larger and may be preferred in applications where manual assembly is more common or where higher power ratings are required.

2. Different Resistance Values and Ratings

Spot fuse resistors are available in a wide range of resistance values and power ratings. Selecting the appropriate resistance value is crucial for ensuring that the resistor will blow at the desired current level.

3. Material Composition

The material composition of spot fuse resistors can vary, with common types including metal film and carbon film. Metal film resistors generally offer better stability and tolerance, while carbon film resistors may be more cost-effective for certain applications.

III. Key Factors to Consider When Choosing Spot Fuse Resistors

When selecting spot fuse resistors, several key factors must be considered to ensure optimal performance.

A. Resistance Value

1. Importance of Accurate Resistance

The resistance value is critical in determining the current threshold at which the resistor will blow. An inaccurate resistance value can lead to premature failure or insufficient protection.

2. How to Calculate Required Resistance

To calculate the required resistance, use Ohm's Law (V = IR). Determine the maximum allowable current and the voltage across the resistor to find the appropriate resistance value.

B. Power Rating

1. Understanding Power Dissipation

Power dissipation is the amount of power the resistor can handle without overheating. It is essential to choose a resistor with a power rating that exceeds the expected power dissipation in your application.

2. Selecting the Right Power Rating for Your Application

Consider the worst-case scenario for your circuit to ensure that the selected resistor can handle the maximum power without failure.

C. Temperature Coefficient

1. Definition and Importance

The temperature coefficient indicates how much the resistance value changes with temperature. A low temperature coefficient is desirable for applications requiring stable performance across varying temperatures.

2. How Temperature Affects Resistance

As temperature increases, the resistance of most materials also increases. Understanding this relationship is crucial for applications exposed to fluctuating temperatures.

D. Tolerance

1. Definition of Tolerance in Resistors

Tolerance refers to the allowable deviation from the specified resistance value. A lower tolerance indicates a more precise resistor.

2. Choosing the Right Tolerance for Your Needs

Select a tolerance that meets the requirements of your application. For critical applications, a tighter tolerance may be necessary.

E. Size and Form Factor

1. Impact of Size on Circuit Design

The physical size of the resistor can impact the overall design of your circuit. Ensure that the chosen resistor fits within the available space without compromising performance.

2. Choosing Between Surface Mount and Through-Hole Options

Consider the assembly process and space constraints when deciding between surface mount and through-hole resistors.

IV. Environmental Considerations

When selecting spot fuse resistors, it is essential to consider the environmental conditions in which they will operate.

A. Operating Temperature Range

Ensure that the resistor can operate within the temperature range of your application. Exceeding this range can lead to failure.

B. Humidity and Moisture Resistance

In humid environments, moisture can affect resistor performance. Choose resistors with appropriate moisture resistance ratings for such applications.

C. Chemical Resistance

If the resistor will be exposed to chemicals, select materials that can withstand such exposure without degrading.

D. Compliance with Industry Standards

Ensure that the selected resistors comply with relevant industry standards, such as RoHS and REACH, to meet regulatory requirements.

V. Application-Specific Considerations

Different applications may have unique requirements for spot fuse resistors.

A. Consumer Electronics

In consumer electronics, size and cost are often critical factors. Spot fuse resistors must be compact and affordable while providing reliable protection.

B. Automotive Applications

Automotive applications require resistors that can withstand harsh conditions, including temperature extremes and vibrations. Choose resistors with robust construction and high reliability.

C. Industrial Equipment

For industrial applications, durability and power handling capabilities are paramount. Select resistors that can handle high power levels and operate reliably in demanding environments.

D. Medical Devices

In medical devices, precision and reliability are crucial. Spot fuse resistors must meet stringent safety and performance standards.

VI. Testing and Validation

A. Importance of Testing Spot Fuse Resistors

Testing is essential to ensure that the selected spot fuse resistors perform as expected in real-world applications.

B. Common Testing Methods

1. Resistance Measurement

Use precision measurement tools to verify the resistance value of the selected resistor.

2. Power Rating Testing

Conduct tests to ensure that the resistor can handle the expected power levels without failure.

C. Validation in Real-World Applications

Validate the performance of spot fuse resistors in actual circuit conditions to ensure reliability and effectiveness.

VII. Common Mistakes to Avoid

A. Overlooking Power Ratings

One of the most common mistakes is selecting a resistor with an insufficient power rating, leading to premature failure.

B. Ignoring Temperature Coefficients

Failing to consider temperature coefficients can result in inaccurate resistance values under varying conditions.

C. Choosing the Wrong Form Factor

Selecting the wrong form factor can lead to assembly issues and may not fit within the design constraints.

D. Failing to Test and Validate

Neglecting to test and validate resistors can result in unexpected failures in the field.

VIII. Conclusion

Choosing the right spot fuse resistor is a critical step in ensuring the reliability and performance of electronic circuits. By understanding the various factors involved, including resistance value, power rating, temperature coefficient, and environmental considerations, you can make informed decisions that will enhance your designs.

Conduct thorough research and testing to avoid common pitfalls and ensure that your selected components meet the demands of your specific applications. With careful consideration and validation, you can confidently integrate spot fuse resistors into your electronic designs, providing the protection and reliability that modern devices require.

IX. References

A. Suggested Reading and Resources

- "Electronic Components: A Complete Reference for Engineers and Technicians" by John Doe

- "Understanding Resistors: A Comprehensive Guide" by Jane Smith

B. Industry Standards and Guidelines

- RoHS Compliance Guidelines

- REACH Regulations

C. Manufacturer Specifications and Datasheets

- Manufacturer A: Spot Fuse Resistor Datasheet

- Manufacturer B: Technical Specifications for Surface Mount Resistors

By following this guide, you can navigate the complexities of selecting spot fuse resistors and ensure that your electronic designs are both safe and effective.